Look at our possibilities.

Specialized in individual manufactures, small and medium series with more than 80 different materials. Everything from one source: from consulting, to production, hardening and tempering, finishing, quality acceptance or your commissioning.

We are pleased to accompany you in expanding on your ideas and your developments.

We want to recognize your problem and increase your benefits.

Your own Pattern shop is important for us. In-house production or external processing with the materials wood, plastic, composite, metal, polystyrene/ Exporit as one-off designs, modifications and repairs to be able to react competently, flexibly and quickly to changes and customer requirements. Your models are safely stored in our new model hall. In the meantime our inventory of models has increased to some 10,000 units.

Machine shapes

Vibro-compaction process

Bentonite (greensand)

Molding boxes:

680 x 620 mm, H 450 - 1.100 mm

1.400 x 900 mm, H 550 - 1.200 mm

1.400 x 1.100 mm, H 700 mm

Unit weight:

from ca. 10 kg to ca. 800 kg

Hand molds

Furan

Molding boxes:

800 x 800 mm

5.000 x 2.600 mm, H 2.500 mm

Unit weight:

from ca. 100 kg to ca. 8 t

2 electric arc furnaces

Loading capacity 2-4 t and 4-6 t

Analysis of melt with spectrometer and thermal elements

more than 80 different materials – there could be another one for you.

In particular in the grinding shop, effective and efficient workflows are important for strict adherence to delivery dates. Our planning team always has your deadline in mind. We communicate with each other openly and quickly. For our staff members we have implemented the latest findings of how to humanize the working world. Optimally designed workstations ensure that the fettler is not exposed to an ergonomically unhealthy posture or excessive strain. Good working conditions are fundamental for motivated staff members. This is supported by our health and safety policy:

Along with the melting process the coordinated heat treatment is the basis for highest steel quality of our materials. With our heat treatment possibilities we also offer versatile product characteristics and a permanent continuity of quality.

The following systems are available for you:

Annealing furnaces

| Löcher IV | LxWxH | 5.000 x 2.700 x 1.500 mm |

| Löcher V | LxWxH | 4.800 x 2.700 x 1.500 mm |

Heat-treatment furnaces

| Löcher I | LxWxH | 4.500 x 2.400 x 1.600 mm |

| Löcher II | LxWxH | 4.000 x 2.000 x 1.200 mm |

| Löcher III | LxWxH | 4.000 x 2.000 x 1.200 mm |

| Naber 21 | LxWxH | 350 x 250 x 250 mm |

| Naber 321 | LxWxH | 1.100 x 750 x 400 mm |

| Oil tank | L = 4.500 mm, W = 2.600 mm | max. 6 t |

| Water tank | L = 4.700 mm, W = 3.000 mm | |

| L = 4.100 mm, W = 3.000 mm | ||

| Air | Stationary | |

| Moving |

We would be happy to perform paid heat treatment on your behalf.

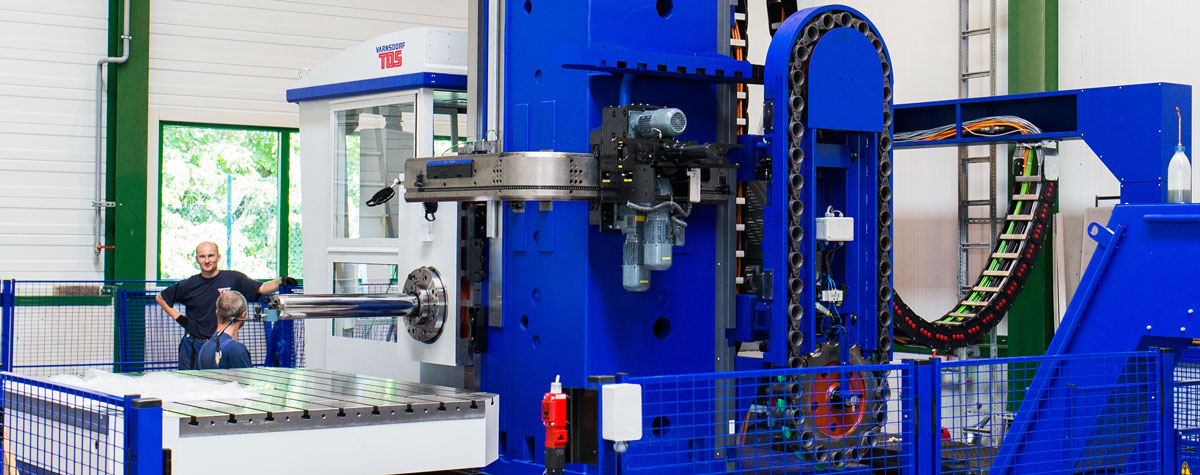

During the last years we have been consistently pursuing our strategy to specifically increase the benefit and the satisfaction of our customers. One priority has been and still is to further develop our possibilities of mechanical pre-machining and/or finishing.

Everything from one source is for you

• less coordination effort and therefore

• time saving and

• low procurement costs, as well as

• shorter delivery periods due to loss of transportation times between different production sites, but also

• better adherence to delivery dates.

More than 20 conventional and state-of-the-art

processing machines are available in Eschweiler at any one time:

CNC bed-type milling machines

CNC high performance bed-type milling machine

CNC drilling and milling machines

CNC horizontal milling machine

CNC two-column vertical lathe

CNC turning machines

CNC lathes

Vertical lathes

Lathes

Boring mills

Arm drill

At present our limits are:

X axis max. 4,000 mm

Y axis max. 2,500 mm

Z axis max. 6,000 mm

W axis max. 800 mm

Table size max. 2,200x1,800 mm and max. 4,100x1,050 mm

Weight max. 25 t

Face plate diameter max. 2,500 mm

Height max. 1.885 mm

Drilling depth max. 1,300 mm

The high quality demands of our customers require extensive quality assurance. We comply with the demands of our customers for high and constant quality of the castings by a very carefully developed working program/process management and strict process controls and component inspections. Monitoring starts with checking the input materials and ends with the output control of the castings. Highly qualified staff members and latest test methods and equipment provide for the required or desired safety.

We regularly check the casting:

Chemical analysis

Material test

Dimensional inspection

Visual test (VT)

Magnetic flaw detection (MT)

Ultrasonic test (UT)

Dye penetrant inspection (PT)

Radiographic test (RT) (external)

Tested quality is assured quality!