Please find below an overview of our machine types. The diversity of systems has been adapted to the current shredder behavior and the desired product variety of our customers.

Our sales team will be pleased to advise you individually with regard to your specific requirements. An individual solution of single units or entire recycling line is paramount in this respect, which at any time also considers any realizable changes of our standard program. This flexibility as to system size and design enables us to react to the most diverse requirements of our customers and offer an optimum solution.

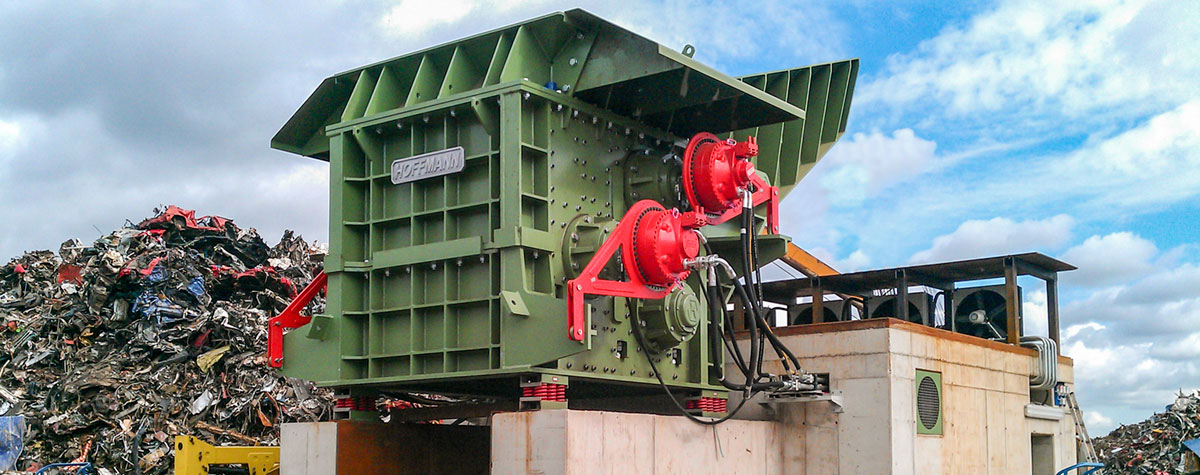

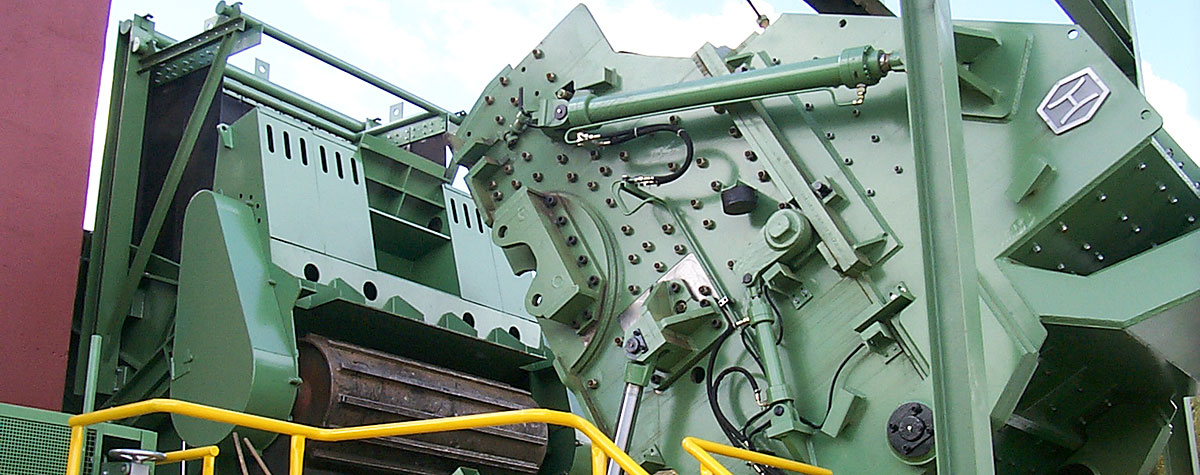

The classic!

For decades this type of shredder has been running and has been continually optimized and adapted to the demands of a shredder system. It is offered as the “standard” and “boost” version with 5 system sizes from 500 to 8000 hp. Boost version in this regard means a larger rotor diameter and working area with the same system size. We would be pleased to advise you on the version that is most suitable for your product! The shredder is characterized by its high shredding degree that enables optimal separation of the different fractions with the connected periphery. This system type still belongs to the systems we sell most, since it breaks down smaller groups that often fall through bottom grids and thus enables successful recycling - also for you. Our sales team will be pleased to inform you personally about the advantages in everyday use and the service life of this Albert Hoffmann system.

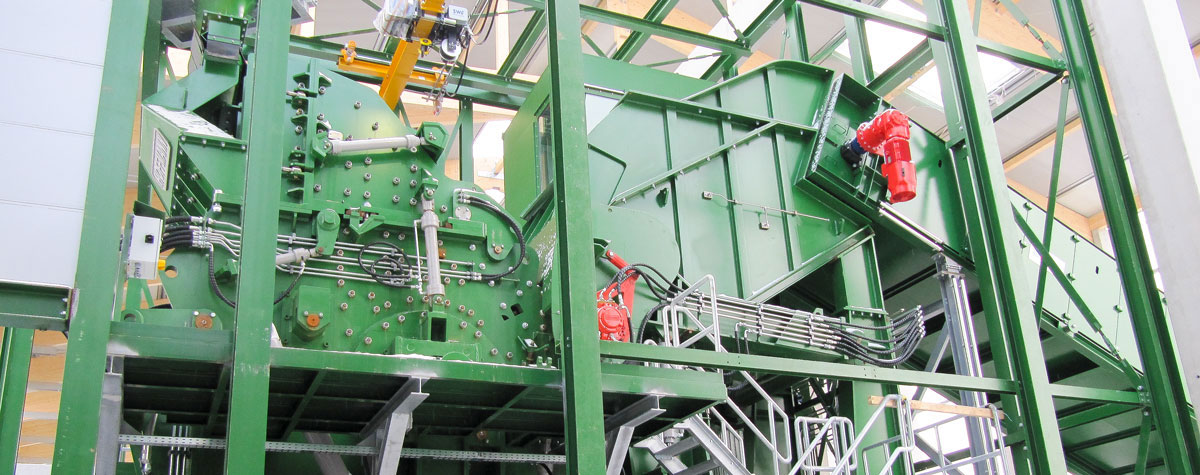

This shredder is our response to highest flexibility while shredding.

Moreover, this system enables continuous granulating (not only granulation by batch by temporarily closing the grid cover) of the most diverse fractions. One example for this is the granulation of the copper fraction of electric motors, on the same system where before a car body might have been shredded. For this a quick-change system from the top grid has been realized which within minutes puts the most diverse patented grid systems into service to adapt to the differently required shredding degrees. The continuous production achieved this way enables highest production and tuning from the product to the following separation. Our sales team will be pleased to inform you personally about the advantages in everyday use and the service life of this Albert Hoffmann system.

Our answer to granulators!

The brilliant answer to many things for which a suitable shredding unit is required. Contact us for trying out your material. Three different system sizes, different rotor diameters and rotor types (2 in 1), variable speed, flexible pipe systems and most comfortable maintenance for this hammer mill.

Whether copper, aluminum or electronic waste fractions, with two horizontal rotors this mill also enables shredding and breaking down the most diverse fractions such as SLF crown caps and cartridge cases - just to mention a few applications. All you have to do is get to know this ingenious unit! Our sales team will be pleased to inform you personally about the advantages in everyday use and the service life of this Albert Hoffmann system.

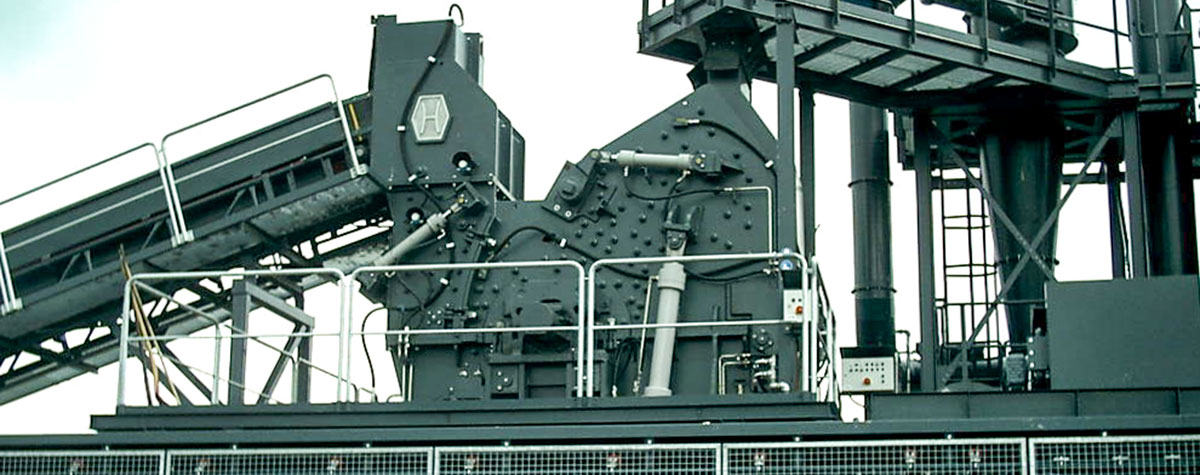

The high performer!

The reworked “standard” and “boost” version of this shredder with top to bottom grids had become the shredding unit with the highest production figures. In this respect, bottom and top grids enable a tuning potential with preferably best break down at highest production. Our sales team will be pleased to inform you personally about the advantages in everyday use and the service life of this Albert Hoffmann system.

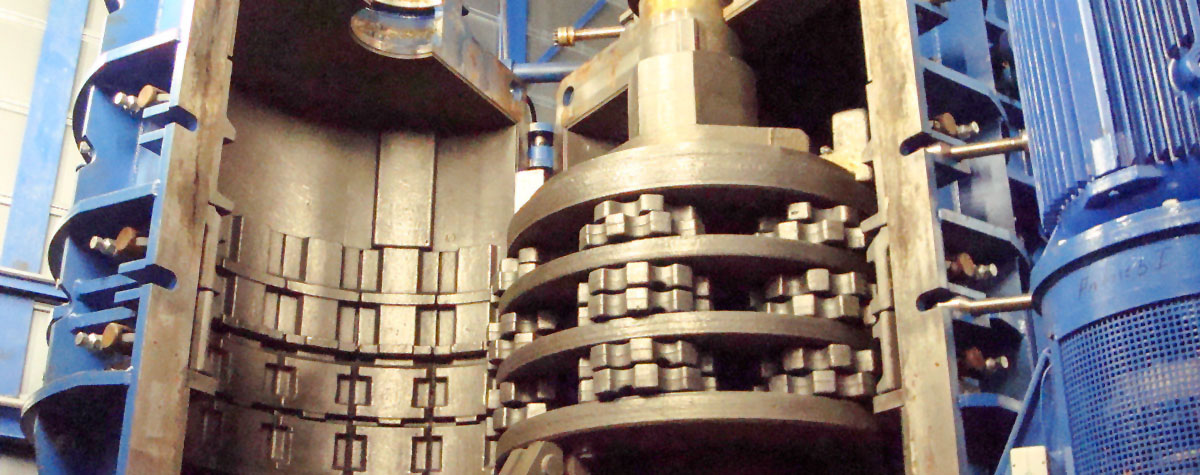

When highest density is paramount!

This vertically running mill is particularly suited for ball shaping (e.g. cooling scrap). By means of selectable chicaneries between impact rings / hammers and the wall lining the material to be shredded is conveyed to the discharge via its dead load. Just recently this mill has become very popular as a powerful machine for many materials. Our sales team will be pleased to inform you about the advantages in everyday use.

The solution for WEEE!

Two sizes of this system are offered. The system is characterized by its mature technology for materials with a high proportion of plastic. Who does not know the risk of unintended fire inside the shredder. Allow yourself to be convinced of our specially movable or patented arc grid. Maybe our double rotor shaft mill is the optimum solution for you! Our sales team will be pleased to inform you personally about the advantages in everyday use and the service life of this Albert Hoffmann system.

The licker-in for explosion reduction!

Our three-shaft pre-shredder is one of the most powerful systems available in the market. These enable high throughput combined with optimum break down of the material. Depending on the requirement, either rough or fine shredding can be selected. Two sizes of the pre-shredder are offered with different drives of up to 1250 kW. Its modular system and changeable spur gears provide for easy maintenance in this respect. The double bearing of the shafts is unique and provides for long-term smooth operation under highest load.

In recent years the pre-shredder has more and more be part of the shredder system. The risk of heavy contaminants and deflagrations in the shredder can be considerably decreased. At the same time pre-shredding leads to a considerable increase of tonnage per hour in the shredder. It can supply the pre-shredded material directly in line to the shredder or stockpile. We offer the pre-shredder in two sizes with different drive power, adapted to meet your requirements.

From tableware to tin cans!

Is the focus of your material to be processed on aluminum scrap? Then we have the right product for you. Due to our long-term experience with our customers operative in this field, we exactly know where we have to focus. Thus we offer numerous extras that make this shredder stand out from a standard shredder.