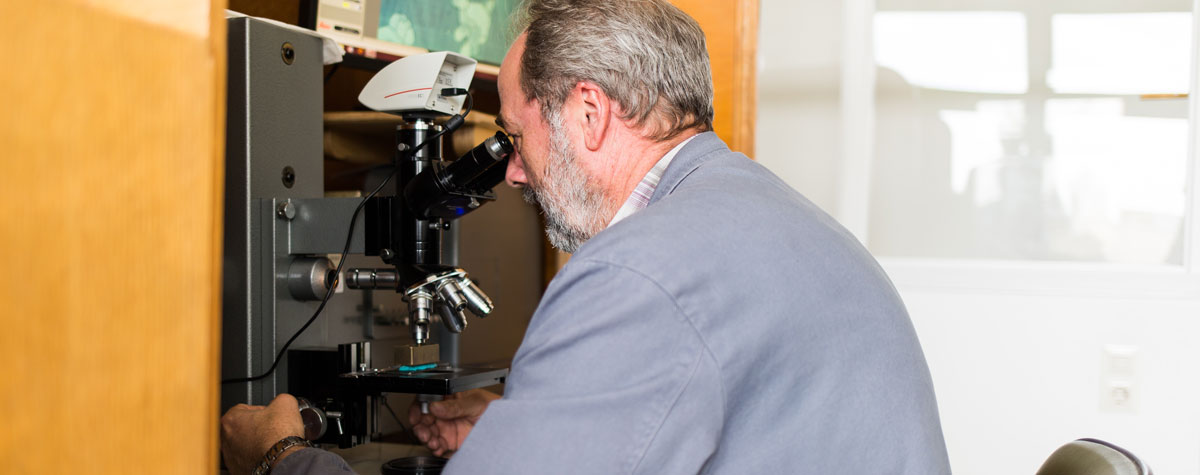

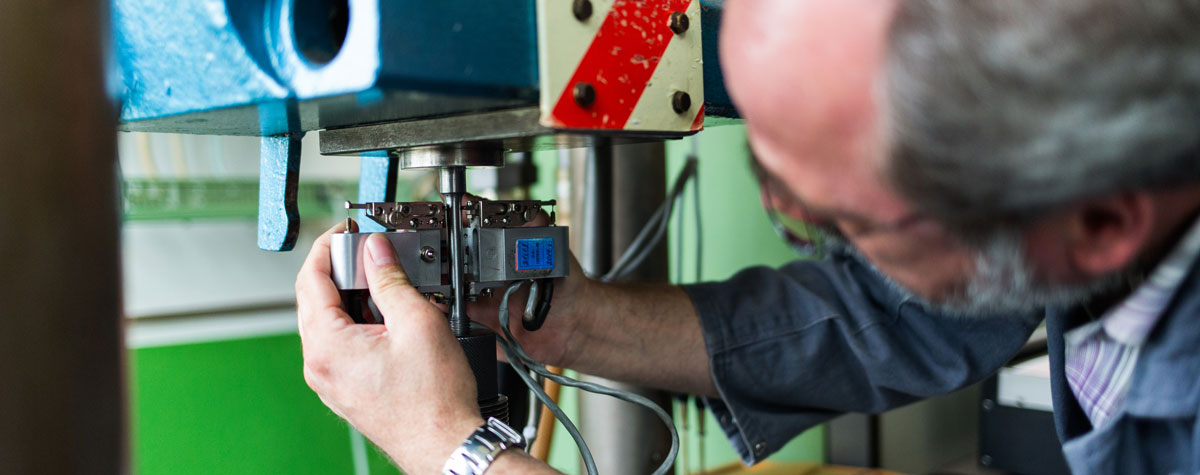

The high quality demands of our customers require extensive quality assurance. We comply with the demands of our customers for high and constant quality of the castings by a very carefully developed working program/process management and strict process controls and component inspections. Monitoring starts with checking the input materials and ends with the output control of the castings. Highly qualified staff members and latest test methods and equipment provide for the required or desired safety.

We regularly check the casting:

Chemical analysis

Material test

Dimensional inspection

Visual test (VT)

Magnetic flaw detection (MT)

Ultrasonic test (UT)

Dye penetrant inspection (PT)

Radiographic test (RT) (external)